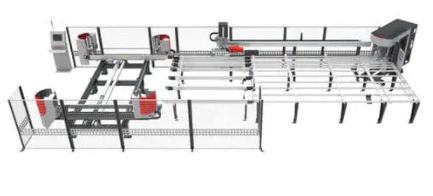

Multiple End Milling Machine

Multiple End Milling Machine Specification

- Product Type

- Multiple End Milling Machine

- Material

- Mild Steel

- Capacity

- Heavy Duty / High Capacity

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual Lever / Switch Control

- Processing Type

- End Milling

- Voltage

- 380V / 415V

- Power

- 3.0 kW - 4.0 kW

- Dimension (L*W*H)

- Approx. 1700 x 900 x 1500 mm

- Weight

- Approx. 800 kg

- Color

- Blue & Grey

- Number of Spindles

- 2 to 4 (Customizable)

- Table Size

- 1000 x 250 mm

- Safety Features

- Emergency Stop, Overload Protection

- Product Application

- Aluminium, PVC, Light Metal Sections

- Cooling System

- Optional Spray/Mist Cooling

- Spindle Speed

- 2800 rpm

- Noise Level

- < 80 dB

- Lubrication System

- Centralized Manual Lubrication

- Feed Type

- Manual / Mechanical

- Clamping Type

- Pneumatic / Manual Clamps

- Milling Cutter Diameter

- 100 mm - 160 mm

Multiple End Milling Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 3 Week

About Multiple End Milling Machine

Grab the preeminent Multiple End Milling Machine and get first-rate performance for demanding industrial tasks! Renowned among suppliers and traders across India, this heavy-duty solution caters to aluminium, PVC, and light metal sections. Personalise your setup with 2 to 4 spindles and choose between pneumatic or manual clamps. Gain control over feed, clamps, and cooling with customizable options. With exceptional spindle speed (2800 rpm) and a robust mild steel build, this semi-automatic unit delivers high capacity, quiet operation, and premium safety. Secure your investment from a top-tier service provider today!

Special Features and Versatile Application

The Multiple End Milling Machine boasts a customizable number of spindles (2 to 4), efficient pneumatic/manual clamping, and manual/mechanical feeding. With a large 1000 x 250 mm table and a cutter diameter range of 100-160 mm, this machine excels on surfaces of aluminium, PVC, and light metal sections. Benefit from optional spray or mist cooling, quiet operation below 80 dB, and advanced safety features, making it ideal for precision milling applications.

Export, Payment, and Domestic Service Highlights

Our Multiple End Milling Machine is mainly exported to various international markets and supplied across India's premier industrial hubs. Contact us for the asking price and detailed charge breakdown. Flexible payment terms are available and transportation arrangements can be customized to suit buyers' requirements. Serving both domestic and export clients, our trading network ensures prompt delivery and after-sales support throughout the region.

Special Features and Versatile Application

The Multiple End Milling Machine boasts a customizable number of spindles (2 to 4), efficient pneumatic/manual clamping, and manual/mechanical feeding. With a large 1000 x 250 mm table and a cutter diameter range of 100-160 mm, this machine excels on surfaces of aluminium, PVC, and light metal sections. Benefit from optional spray or mist cooling, quiet operation below 80 dB, and advanced safety features, making it ideal for precision milling applications.

Export, Payment, and Domestic Service Highlights

Our Multiple End Milling Machine is mainly exported to various international markets and supplied across India's premier industrial hubs. Contact us for the asking price and detailed charge breakdown. Flexible payment terms are available and transportation arrangements can be customized to suit buyers' requirements. Serving both domestic and export clients, our trading network ensures prompt delivery and after-sales support throughout the region.

FAQ's of Multiple End Milling Machine:

Q: How can I customise the number of spindles on the Multiple End Milling Machine?

A: You can select from 2 to 4 spindles per your project requirements when placing your order. Customisation options are discussed during the procurement process.Q: What surfaces and materials can be processed using this milling machine?

A: This machine is suitable for aluminium, PVC, and various light metal sections, making it highly versatile for multiple surface applications.Q: Where is the Multiple End Milling Machine mainly supplied and exported?

A: It is predominantly supplied across India's industrial regions and exported to several international markets through our established trading network.Q: What is the process for arranging payment and transportation?

A: Payment terms vary and can be discussed based on your needs, while transportation and delivery charges are negotiated at the time of order placement for seamless delivery.Q: What safety features are integrated in this milling machine?

A: The machine includes an emergency stop, overload protection, and centralized manual lubrication system, ensuring operator safety and reliable operation.Q: When is it beneficial to use the optional spray/mist cooling system?

A: The spray/mist cooling system is beneficial during intensive milling to manage heat and enhance tool life, especially for continuous operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in UPVC 250 Windows Production Plan Category

Processing Centre for UPVC windows

Price 9700000 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 18 KW Watt (w)

Control System : PLC Control

Computerized : Yes

Weight : 4100 Kilograms (kg)